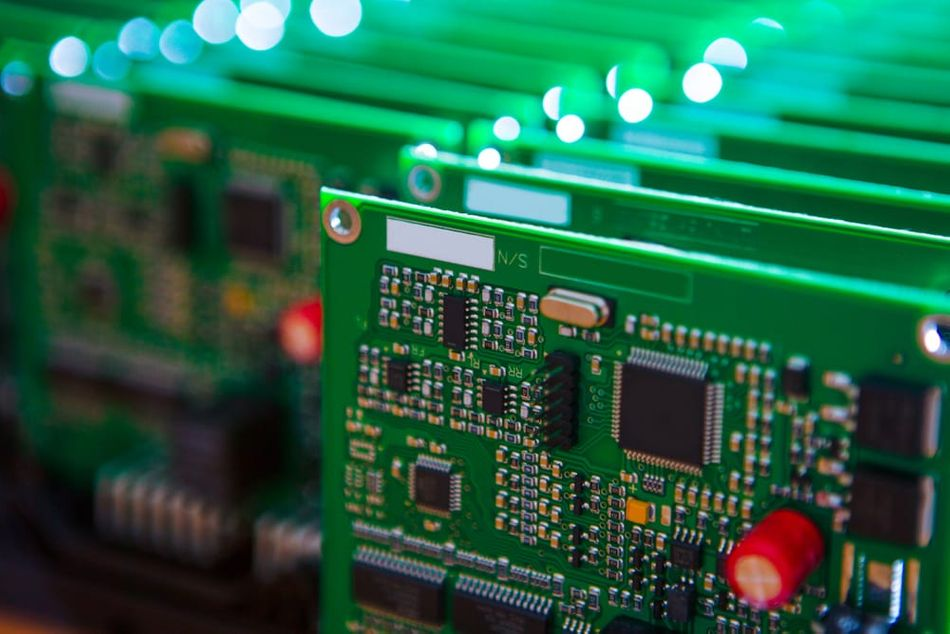

Assembly of Printed Circuit Boards (PCBs): A Comprehensive Guide to Assembling and Understanding Assembled Circuit Boards

Printed Circuit Boards (PCBs) have gotten to be vital in cutting edge hardware. They serve as the spine of essentially each electronic gadget, from keen phones and computers to mechanical machines and domestic apparatuses. The prepare of Assemble PCBS is perplexing and includes numerous stages, each pivotal for guaranteeing that the last item performs as expected.In this comprehensive direct, we will explore the Assembly of printed circuit Boards, specifying the steps included in collecting PCBs and understanding the structure and usefulness of an gathered circuit board.

1. Presentation to Printed Circuit Boards (PCBs)

Printed Circuit Boards (PCBs) are level Boards made from protection materials that mechanically bolster and electrically interface electronic components. They comprise of different layers of copper follows that interface distinctive components together, permitting the stream of power over the board.

PCBs have revolutionized the world of hardware by advertising a compact, effective, and cost-effective way to house and interconnect components. They can run from basic single-layer Boards, utilized in essential applications, to profoundly complex multi-layer Boards found in advanced electronic systems.

2. Significance of PCB Assembly in Electronics

PCB Assembly (PCBA) is the prepare of patching and Assembly the components onto the uncovered PCB board. Without this prepare, a PCB is just a board with conductive follows, incapable to perform any significant work. As it were after components like resistors, capacitors, transistors, coordinates circuits (ICs), and connectors are set and secured onto the board does it gotten to be an operational unit.

PCBs are central to the usefulness of nearly all cutting edge electronic gadgets. Appropriate Assembly guarantees unwavering quality, toughness, and execution. A single imperfection in Assembly seem render a gadget broken, emphasizing the significance of accuracy at each step.

3. Sorts of PCBs

Understanding the different sorts of PCBs is fundamental for getting a handle on the Assembly prepare, as each sort has one of a kind prerequisites. The major sorts of PCBs include:

Single-Layer PCBs

Single-layer PCBs comprise of as it were one layer of conductive copper, which carries signals between diverse components. These are moderately straightforward to plan and are commonly utilized in low-cost applications like calculators and control supplies.

Double-Layer PCBs

Double-layer PCBs have two layers of conductive texture on both sides of the board. This arrangement permits for more complex steering and higher component thickness, making them reasonable for more modern gadgets like car dashboards and amplifiers.

Multi-Layer PCBs

Multi-layer PCBs have three or more layers of copper stacked together with protection fabric in between. These Boards are utilized in high-performance applications such as servers, therapeutic gadgets, and smart phones, as they permit for the integration of progressed highlights and high-speed circuits.

Flexible PCBs

Flexible PCBs, made from versatile materials, can turn and twist without breaking. These are utilized in applications where space is confined or the board needs to be collapsed, such as wearable advancement and versatile phones.

Rigid-Flex PCBs

Rigid-flex PCBs combine the central focuses of both unbendable and versatile Boards. They offer adaptability in plan and vigour, making them reasonable for complex applications like aviation frameworks and restorative equipment.

4. Components of PCBs

Before jumping into the Assembly handle, it’s vital to get it the key components that are commonly set on PCBs:

Resistors

Resistors control the stream of electric current in the circuit by advertising resistance. They are one of the most fundamental and fundamental components in any circuit.

Capacitors

Capacitors store and discharge electrical vitality when required by the circuit. They are pivotal for stabilizing voltage and sifting signals.

Diodes

Diodes permit current to stream in as it were one heading, anticipating potential harm to delicate components by blocking switch current.

Transistors

Transistors act as switches or speakers in electronic circuits. They control the stream of current and are fundamental in computerized rationale circuits and flag processing.

Integrated Circuits (ICs)

ICs are complex circuits that combine numerous components into a single bundle, performing a assortment of capacities depending on the application.

Connectors

Connectors connect diverse PCBs or interface outside gadgets to the PCB, guaranteeing flag transmission between the board and outside peripherals.

5. The PCB Assembly Process

The PCB Assembly handle includes a few steps, from component arrangement to patching, assessment, and testing. Here is a point by point see at each stage:

1. Solder Paste Application

The to begin with step in PCB Assembly is applying patch glue to the board. A stencil is set over the board, and patch glue (a blend of flux and minor patch balls) is connected. The glue follows to regions where components will be mounted.

2. Choose and Place

After applying patch glue, the another step includes putting components on the board. This handle is ordinarily mechanized utilizing pick-and-place machines, which precisely put components onto the PCB based on a pre-programmed plan file.

3. Reflow Soldering

Once all components are in put, the board goes through a reflow stove, where the patch glue is warmed until it dissolves and bonds the components to the PCB. The board is at that point cooled to cement Assemble PCBS the connections.

4. Review and Quality Control

After reflow patching, the board experiences different assessments to check for absconds like misaligned components, patch bridges, and open circuits. Computerized Optical Assessment (AOI) is commonly utilized for this purpose.

5. Through-Hole Component Insertion (if applicable)

For components that cannot be surface-mounted, such as expansive connectors or bulky components, through-hole technology (THT) is utilized. Components are embedded into gaps bored into the board and fastened on the other side.

6. Wave Soldering (for THT components)

For through-hole components, wave patching is regularly utilized. The PCB is passed over a wave of liquid patch, which follows to the uncovered metal cushions and component leads.

7. Last Assessment and Testing

After all components are patched, the board experiences last review and utilitarian testing. This guarantees that the board meets the required determinations and performs as anticipated. Utilitarian tests may include checking flag keenness, control dissemination, and component performance.

6. Surface Mount Technology (SMT)

Surface Mount Technology (SMT) is the most common technique utilized in PCB Assembly these days. In SMT, components are set specifically onto the surface of the board without the required for through-hole associations. This strategy is exceedingly proficient and permits for the Assembly of compact, high-density circuits.

SMT offers a few preferences over conventional through-hole technology:

• Higher component thickness: Components can be set closer together, decreasing the in general estimate of the PCB.

• Faster Assembly: Robotized machines can put components rapidly and precisely, decreasing Assembly time.

• Cost-effective: SMT diminishes the require for manual labor and is more productive in terms of fabric usage.

However, SMT has restrictions, especially when it comes to dealing with bigger or bulkier components that cannot be surface-mounted.

7. Through-Hole Technology (THT)

Through-Hole Technology (THT) includes embeddings component leads into gaps penetrated into the PCB and patching them on the inverse side. THT is ordinarily utilized for components that require a more grounded mechanical bond or are as well huge for SMT.

Advantages of THT include:

• Stronger mechanical association: THT gives a more secure bond, making it perfect for components that may encounter physical stress.

• Suitability for high-power components: THT is frequently utilized for high-power components like transformers and capacitors, which cannot be effectively surface-mounted.

However, THT is more labour-intensive and takes up more space on the board compared to SMT.

8. Review and Testing of Assembled PCBs

Inspection and testing are basic stages in PCB Assembly to guarantee the quality and usefulness of the last item. A few strategies are utilized to identify surrenders and confirm performance:

Automated Optical Inspection (AOI)

AOI employments high-resolution cameras to capture pictures of the PCB and compare them to the plan records. This handle can distinguish abandons like misaligned components, lost parts, or patch bridges.

X-Ray Inspection

X-ray assessment is utilized to assess covered up patch joints, especially for components like Ball Grid Arrays (BGAs), where the patch associations are not visible.

In-Circuit Testing (ICT)

In-circuit testing includes applying electrical tests to particular test focuses on the PCB to degree parameters like voltage, current, and resistance. ICT can rapidly recognize issues like open circuits or brief circuits.

Functional Testing

Functional testing includes controlling up the PCB and running it beneath reenacted working conditions to confirm that it performs as expected.

9. Common Abandons and Arrangements in PCB Assembly

Even with robotized forms, abandons can happen amid PCB Assembly. A few of the most common surrenders include:

Solder Bridges

Solder bridges happen when abundance patch makes an unintended association between two adjoining cushions, driving to a brief circuit. This can be maintained a strategic distance from by controlling the sum of patch glue connected and guaranteeing precise component placement.

Cold Patch Joints

Cold patch joints happen when the patch does not appropriately bond to the component or cushion, coming about in destitute electrical associations. This can be anticipated by guaranteeing the reflow broiler is set to the rectify temperature and that the components are legitimately adjusted some time recently soldering.

Tomb stoning

Tomb stoning happens when one conclusion of a little component lifts off the board amid reflow fastening. This can be caused by uneven warming or disgraceful stencil plan. Altering the warming profile and guaranteeing indeed patch glue conveyance can offer assistance avoid tomb stoning.

Misaligned Components

Misaligned components can lead to destitute patch associations or indeed total disappointment of the circuit. This issue can be minimized by utilizing progressed pick-and-place machines and performing exhaustive assessments some time recently reflow soldering.

10. The Future of PCB Assembly

The future of PCB Assembly is promising, with headways in innovation proceeding to thrust the boundaries of what is conceivable. A few key patterns include:

Miniaturization

As gadgets gotten to be littler and more effective, the request for littler and more complex PCBs is expanding. This is driving advancements in component situation, fabric science, and Assembly techniques.

Flexible and Wearable Electronics

Flexible PCBs are getting to be progressively vital in wearable hardware and other applications where conventional inflexible Boards cannot be utilized. The improvement of modern materials and Assembly forms is empowering the creation of adaptable circuits that can withstand bowing and bending without losing functionality.

Automation and Robotics

The proceeded integration of robotization and mechanical technology in PCB Assembly is progressing productivity, exactness, and cost-effectiveness. As machines gotten to be more competent, the dependence on human labour for Assembly will diminish, driving to speedier generation times and less defects.

Environmental Considerations

Sustainability is getting to be a key thought in PCB fabricating and Assembly. The industry is moving towards the utilize of lead-free patch, recyclable materials, and energy-efficient generation forms to decrease the natural affect of gadgets manufacturing.

11. Conclusion

The Assembly of printed circuit Boards is a crucial handle that lies at the heart of advanced PCB Assembly gadgets. From straightforward single-layer Boards to complex multi-layer plans, PCBs frame the establishment of for all intents and purposes all electronic gadgets. The Assembly handle includes different stages, from patch glue application and component arrangement to patching, review, and testing.

By understanding the complexities of PCB Assembly, producers can guarantee that their items are dependable, productive, and competent of assembly the requests of today's technology-driven world. As the industry proceeds to advance, modern progressions in miniaturization, adaptable hardware, robotization, and supportability will shape the future of PCB Assembly, opening up energizing conceivable outcomes for advancement in electronic plan and manufacturing.